Plug Gauge Calibration Tolerances . a plug gage is a cylinder designed to check the component tolerance of a hole in a product. Master gages tolerance is split 50/50. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. To calculate gage tolerances, the general rule of thumb is to use 10% of your part. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances. The plug gage has been found to.

from www.sumipol.com

To calculate gage tolerances, the general rule of thumb is to use 10% of your part. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. The plug gage has been found to. a plug gage is a cylinder designed to check the component tolerance of a hole in a product. Master gages tolerance is split 50/50. among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances.

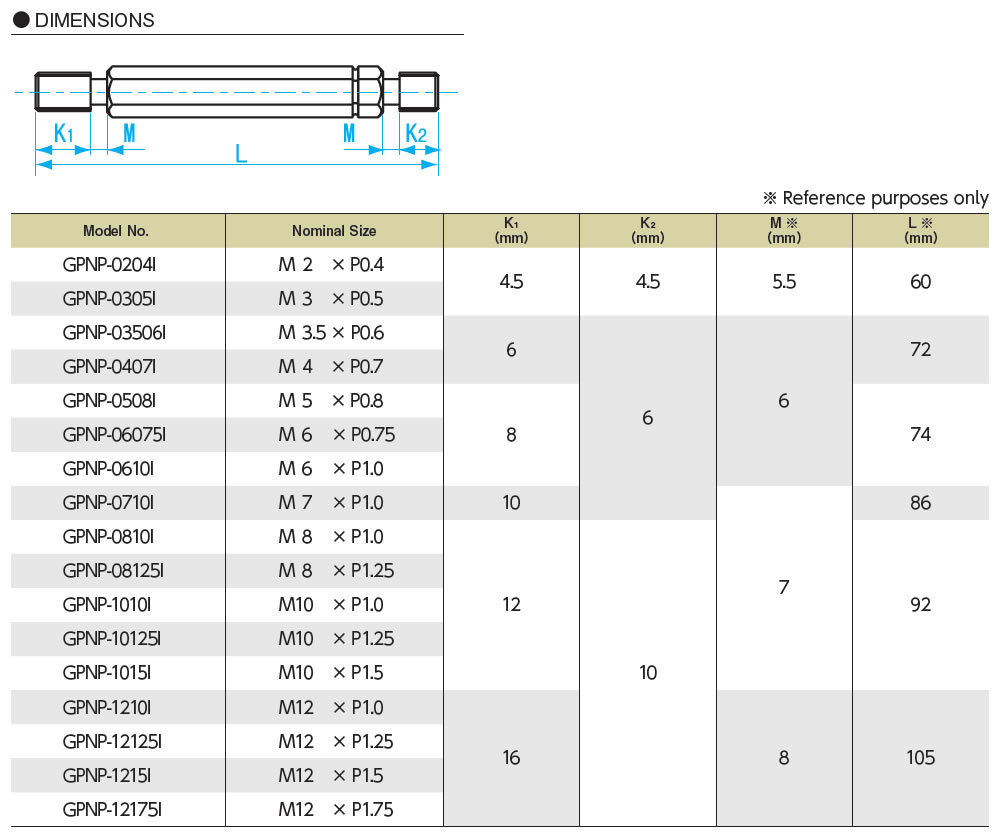

THREAD LIMIT PLUG GAUGEISO TYPE JISGPNPspec Sumipol

Plug Gauge Calibration Tolerances one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. The plug gage has been found to. Master gages tolerance is split 50/50. a plug gage is a cylinder designed to check the component tolerance of a hole in a product. among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances. To calculate gage tolerances, the general rule of thumb is to use 10% of your part.

From www.alibaba.com

Metric Thread Plug Gauge Standard Tolerances 6h Go Nogo 6g Ring Gauge Plug Gauge Calibration Tolerances one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. among these tools, plug gages stand out for their critical role in assessing component conformity to. Plug Gauge Calibration Tolerances.

From mavink.com

Plug Gauge Tolerance Chart Plug Gauge Calibration Tolerances To calculate gage tolerances, the general rule of thumb is to use 10% of your part. Master gages tolerance is split 50/50. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. among these tools, plug. Plug Gauge Calibration Tolerances.

From jarnalmensal.com

Ø60mm Smooth Plug Gauge Plug Gage Tolerance H7 Select Size Ø2mm Plug Gauge Calibration Tolerances there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. The plug gage has been found to. among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances. one of our most frequently asked question is “which gagemaker class of tolerance. Plug Gauge Calibration Tolerances.

From www.alibaba.com

Metric Thread Plug Gauge Standard Tolerances 6h Go Nogo 6g Ring Gauge Plug Gauge Calibration Tolerances To calculate gage tolerances, the general rule of thumb is to use 10% of your part. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. The plug gage has been found to. cylindrical. Plug Gauge Calibration Tolerances.

From mungfali.com

Gage Block Tolerance Chart Plug Gauge Calibration Tolerances Master gages tolerance is split 50/50. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. The plug gage has been found to. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. cylindrical plug gage go member is to the plus side, nogo. Plug Gauge Calibration Tolerances.

From mavink.com

Plug Gauge Tolerance Chart Plug Gauge Calibration Tolerances one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. The plug gage has been found to. Master gages tolerance is split 50/50. diameter tolerance chart. Plug Gauge Calibration Tolerances.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Plug Gauge Calibration Tolerances To calculate gage tolerances, the general rule of thumb is to use 10% of your part. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. . Plug Gauge Calibration Tolerances.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Plug Gauge Calibration Tolerances Master gages tolerance is split 50/50. one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain. Plug Gauge Calibration Tolerances.

From www.qualitymag.com

Calibrating Standard Threaded Gages 20200501 Quality Magazine Plug Gauge Calibration Tolerances a plug gage is a cylinder designed to check the component tolerance of a hole in a product. among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. Master gages. Plug Gauge Calibration Tolerances.

From basicstomechanicalengineering.blogspot.com

Mechanical Engineering Basics International Tolerance Grade Plug Gauge Calibration Tolerances one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances. The plug gage has been found to. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator. Plug Gauge Calibration Tolerances.

From www.indiamart.com

Plain Plug Gauge Snap Gauge Thread Gauge at Rs 950 Measuring Plug Gauge Calibration Tolerances cylindrical plug gage go member is to the plus side, nogo member is to the minus side. a plug gage is a cylinder designed to check the component tolerance of a hole in a product. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. among these tools, plug gages stand out. Plug Gauge Calibration Tolerances.

From www.teachtoearn.in

Gagemakers Tolerance Chart Willich Precision Instruments, 40 OFF Plug Gauge Calibration Tolerances there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. among these tools, plug gages stand out for their critical role in assessing component conformity to. Plug Gauge Calibration Tolerances.

From mavink.com

Plug Gauge Tolerance Chart Plug Gauge Calibration Tolerances cylindrical plug gage go member is to the plus side, nogo member is to the minus side. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. To calculate gage tolerances, the general rule of thumb is to use 10% of your part. among these tools, plug gages stand out for their critical. Plug Gauge Calibration Tolerances.

From rsvautomotive.co.uk

Business & Industrial CNC, Metalworking & Manufacturing 2 3/48 UN Plug Gauge Calibration Tolerances a plug gage is a cylinder designed to check the component tolerance of a hole in a product. Master gages tolerance is split 50/50. The plug gage has been found to. To calculate gage tolerances, the general rule of thumb is to use 10% of your part. diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for. Plug Gauge Calibration Tolerances.

From www.sumipol.com

THREAD LIMIT PLUG GAUGEISO TYPE JISGPNPspec Sumipol Plug Gauge Calibration Tolerances one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. To calculate gage tolerances, the general rule of thumb is to use 10% of your part. among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances. a. Plug Gauge Calibration Tolerances.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Plug Gauge Calibration Tolerances cylindrical plug gage go member is to the plus side, nogo member is to the minus side. there are many dimensional characteristics on a threaded plug gage that can be measured, but the two most common. among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances. To calculate gage. Plug Gauge Calibration Tolerances.

From exovsazwm.blob.core.windows.net

Metric Thread Plug Gauge Standard Tolerances at Alvin McGee blog Plug Gauge Calibration Tolerances among these tools, plug gages stand out for their critical role in assessing component conformity to specified tolerances. a plug gage is a cylinder designed to check the component tolerance of a hole in a product. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. one of our. Plug Gauge Calibration Tolerances.

From www.alibaba.com

Metric Thread Plug Gauge Standard Tolerances 6h Go Nogo 6g Ring Gauge Plug Gauge Calibration Tolerances a plug gage is a cylinder designed to check the component tolerance of a hole in a product. one of our most frequently asked question is “which gagemaker class of tolerance should be used for selecting plain plug and ring. To calculate gage tolerances, the general rule of thumb is to use 10% of your part. cylindrical. Plug Gauge Calibration Tolerances.